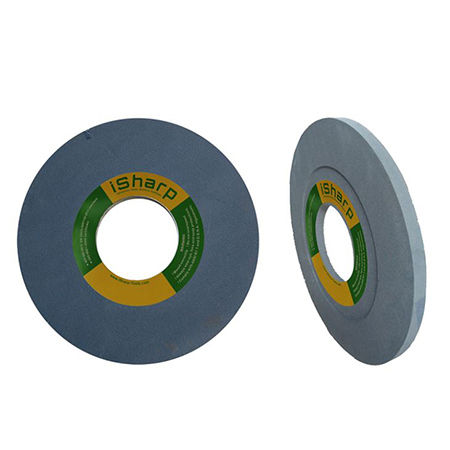

aluminum oxide grinding wheel

Product Details:

aluminum oxide grinding wheel Price And Quantity

- 2 USD ($)/Piece

- 5.00 - 10.00 USD ($)/Piece

- 10 Piece

Product Description

Product description:

Application of White Aluminum Oxide Grinding Wheel:

Vitrified bond aluminum oxide grinding wheel for bench grinder, is mainly used on horizontal grinder, vertical grinder and surface grinder, grinding wheel surrounding and end surface as grinding working surface. Applied materials: Cast iron, hardness steel, soft steel, nonferrous metal,stainless steel,high speed steel, die steel, malleable iron, steel castings, tool, alnico, bronze, chrome plate, and brass, etc.

Specifications of White Aluminum Oxide Grinding Wheel:

| Type 1 | Diameter (mm) | Hole(mm) | Thickness(mm) |

| 250 | 32 | 25/35 | |

| 300 | 75/76.2/127 | 32/40/50 | |

| 350 | 75/76.2/127/203 | 32/40/50 | |

| 400 | 127/160/203 | 32/40/50/63 | |

| 450 | 203/254/305 | 32/40/50/63/75 | |

| 500 | 305 | 32/40/50/63/75/100 | |

| 600 | 305 | 32/40/50/63/75/100/125 | |

| 650 | 305 | 33/40 | |

| 750 | 305 | 22/25/28/33/40/43/58/61/67/86 | |

| 900 | 305 | 22/25/28/32/33/38/40/42/43/47/52/55/58/61/72/75/78/82/90 | |

| 1065 | 304.8 | 22/25/32/38/42/47/52/55 | |

| 1100 | 305 | 25/32/33/38/40/43/55/58/61/72/75/82/86/90 | |

| 1200 | 305 | 120/150 | |

| 1250 | 305 | 42/75/80 | |

| 1400 | 305 | 80/86/120 | |

| 1600 | 305 | 80/86/120 | |

| 1600 | 900 | 86/90/120 | |

| 1800 | 305 | 90/120 |

Special Sizes can be made on the customer's requirements.

Abrasive Materials of White Aluminum Oxide Grinding Wheel:

Aluminum oxide and silicon carbide are the two main bench grinding wheel abrasives used in manufacturing. These abrasives precisely control the shape and physical properties of the abrasive grains.

1. Aluminum oxide is the most popular abrasive and is generally recommended for grinding most steels, annealed iron, malleable and ductile iron, and non-ferrous cast alloys.

2. White aluminum oxide is a highly refined aluminum oxide, this white abrasive has exceptionally fast and cool cutting and grinding properties, especially suitable for grinding operations on hardened steel or high-speed steel in various precision grinding.

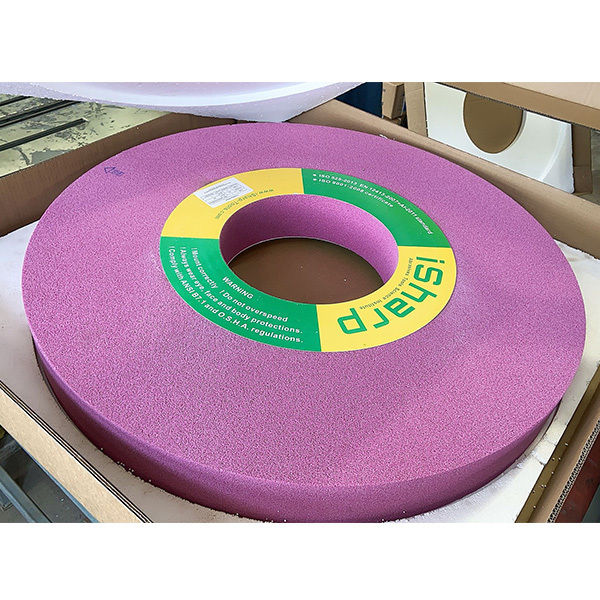

3. Pink aluminum oxide is slightly harder and less brittle than white abrasives, while still maintaining its machinability characteristic. This is especially suitable for grinding wear-resistant, heat-sensitive tool steels.

There are two types of silicon carbide, black silicon carbide "C" and green silicon carbide "GC".

4. Black silicon carbide is very hard and more brittle than aluminum oxide. It is used for general grinding, heavy stuck drill, external cylindrical, centerless, internal cylindrical grinding, also for non-ferrous materials, cast iron, stainless steel and rough grinding applications.

5. Green silicon carbide is also hard and brittle. Suitable for hard, high-cooled cast iron, rolls, etc.

FAQ

1. who are we?

We are based in Henan, China, start from 2013,sell to Domestic Market(20.00%),Western Europe(13.00%),Mid East(10.00%),Eastern Europe(10.00%),North America(9.00%),South Asia(7.00%),Southeast Asia(6.00%),Southern Europe(5.00%),Central America(5.00%),Oceania(5.00%),Africa(5.00%),South America(3.00%),Eastern Asia(2.00%). There are total about 301-500 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Honing stone, Grinding wheel, grinding wheel making machine,flap disc machine,coated abrasive machinery, abrasive tools, cutting discs

4. why should you buy from us not from other suppliers?

Experienced abrasives engineers constitute a research team from 1991. Adhering to the "Green, Efficiency, Precision" concept, we design, develop and produce suitable abrasive products, provide a complete grinding technology services.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,CPT,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,Western Union,Cash;

Language Spoken:English,Chinese

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese